No items match that criteria

Featured Model Specifications

Rated Power, Net

171.6 hp @ 2100 rpm

Operating Weight

171.6 hp @ 2100 rpm

Operating Weight

31349 lb

Bucket Capacity

31349 lb

Bucket Capacity

3.27 yd³

3.27 yd³

Specifications for DL250TC-7 Wheel Loader

-

{{ massageBrand(model.brandName) }}

Current Model {{ model.modelId }}

- {{ massageBrand(compareModel1.brandName) }}

- {{ massageBrand(compareModel2.brandName) }}

{{cat.name }}

-

- {{ specs.name }}

- {{ ((isMetric ? specs.configurations[0].metricValue : specs.configurations[0].imperialValue ) || '--') }}

- {{ getSpec(compareModel1, cat.name, specs.searchNameId, isMetric) }}

- {{ getSpec(compareModel2, cat.name, specs.searchNameId, isMetric) }}

Overview

Versatile Performance in Demanding Applications

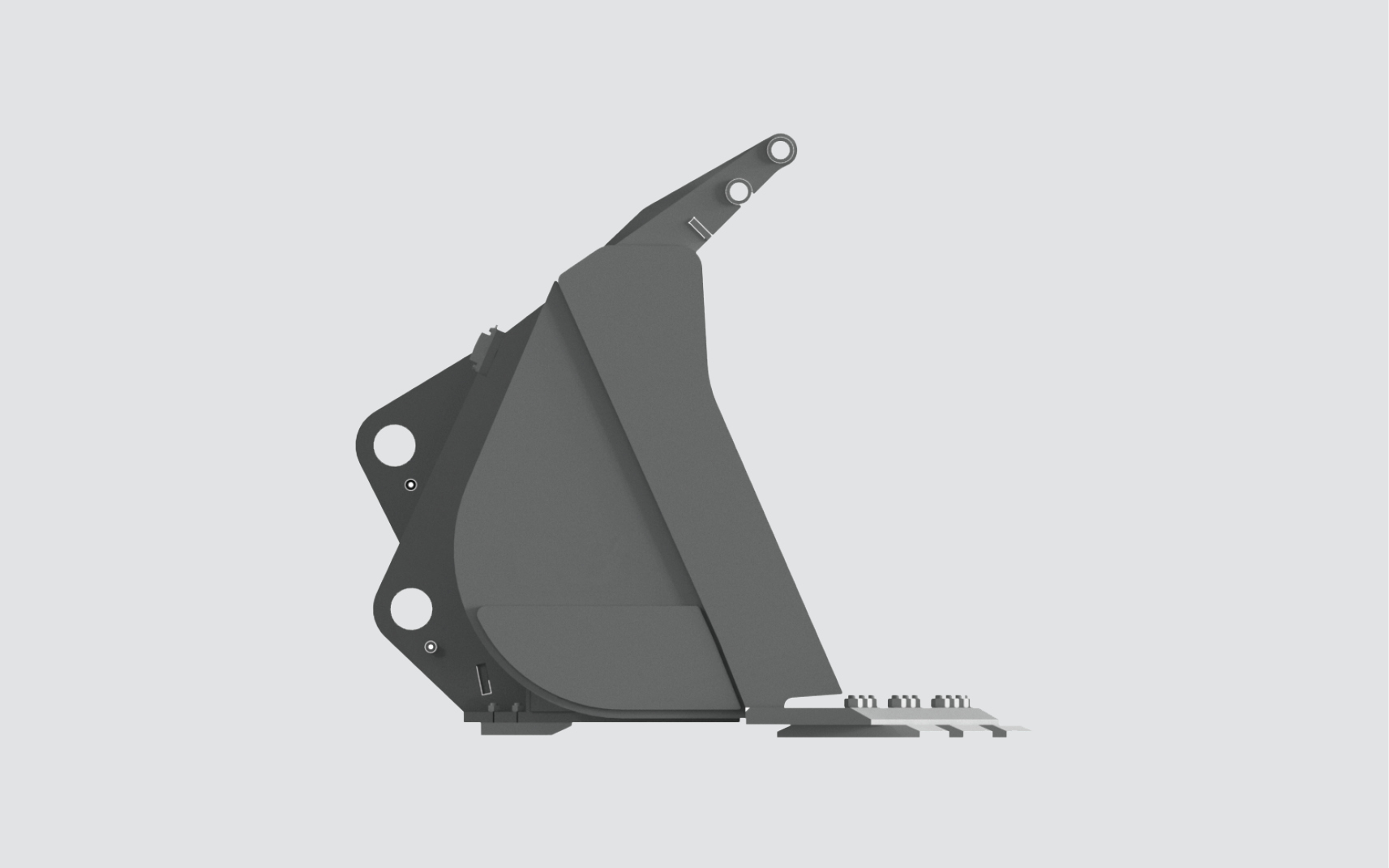

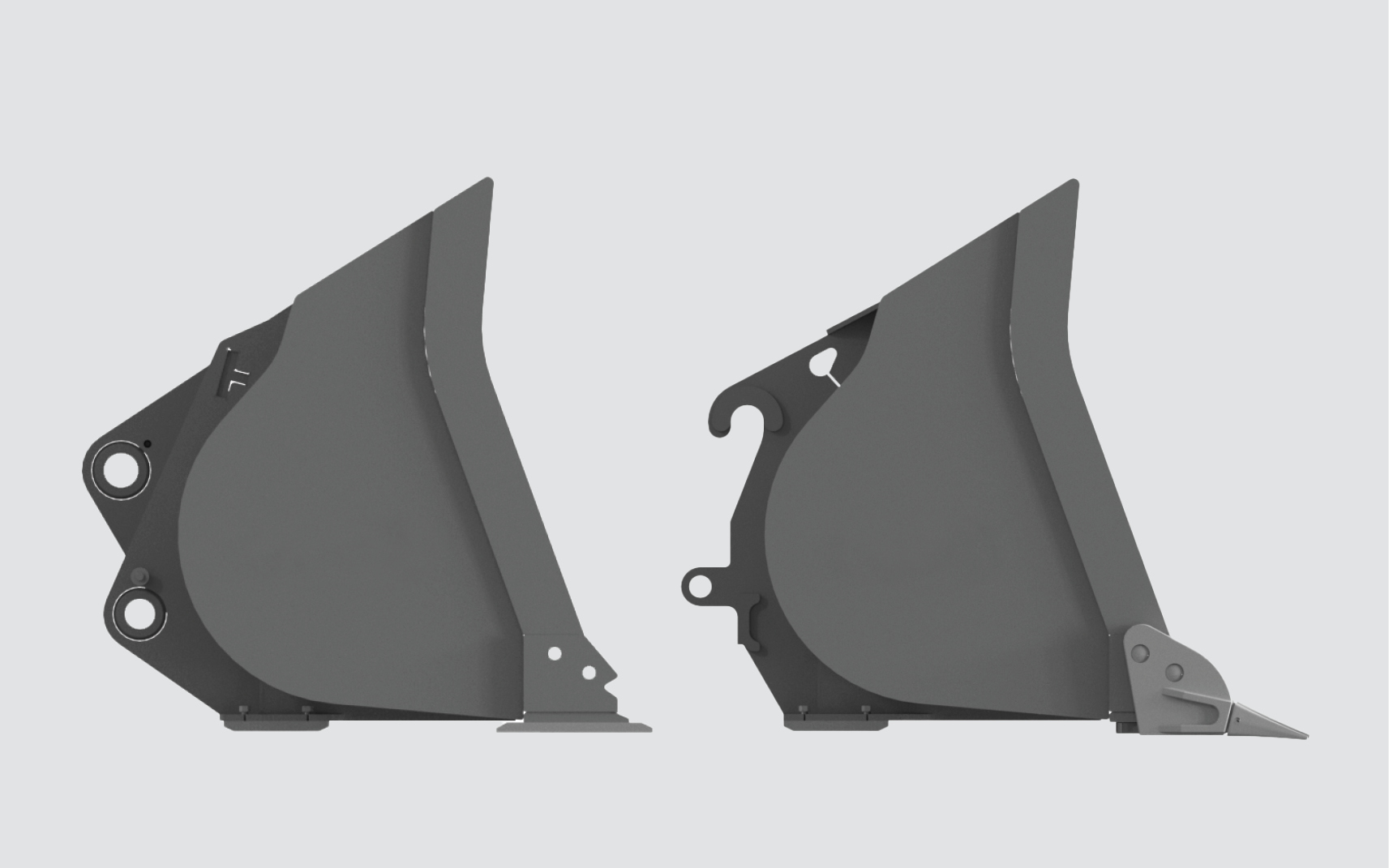

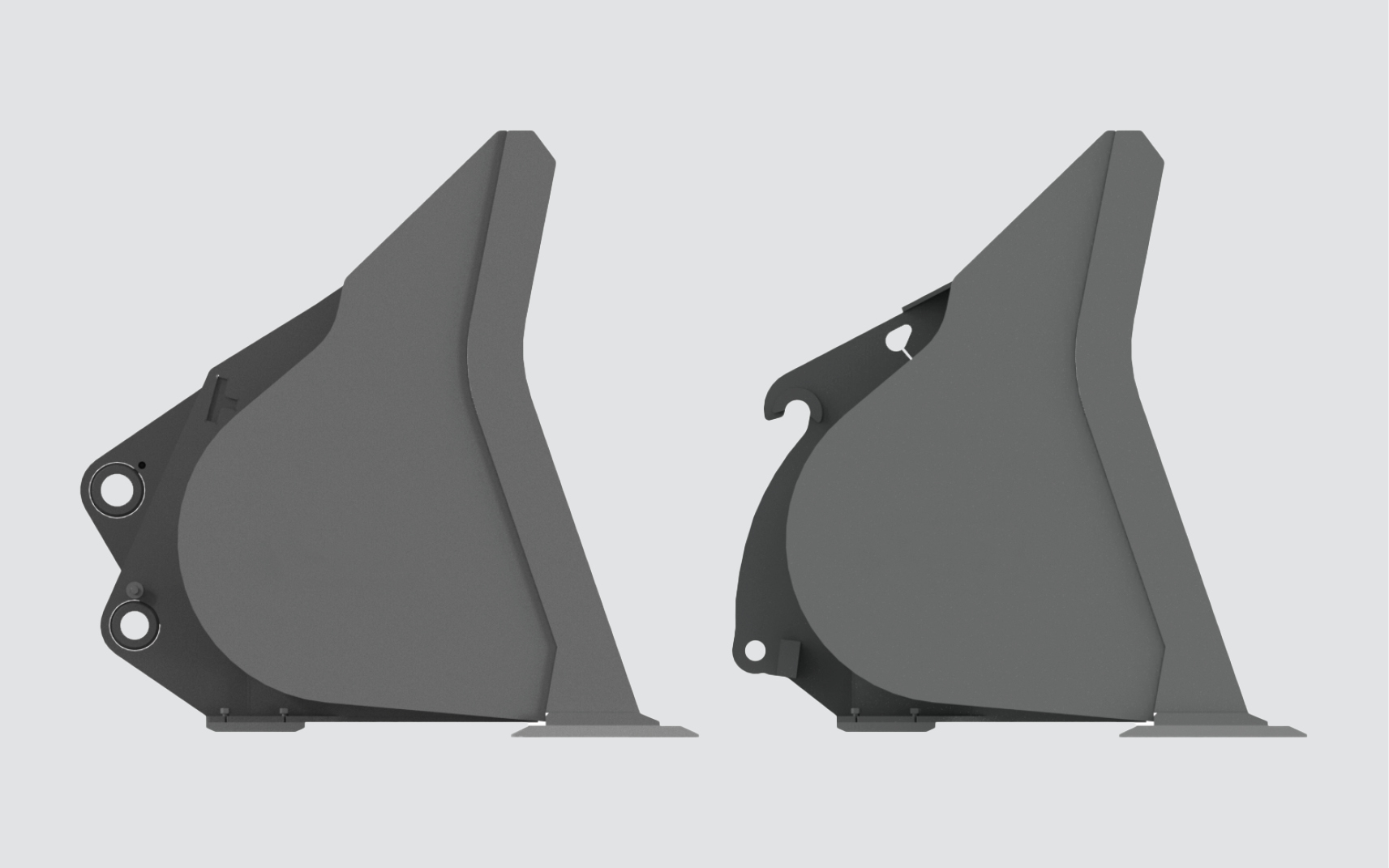

The 3.3-cubic-yard DL250TC-7 articulating wheel loader features a parallel-lift linkage system that allows it to more precisely operate a variety of attachments in applications other than loading, such as lift and place-type operations.

The optional quick coupler is available for quickly changing non-hydraulic attachments.

It delivers heavy lifting in construction and agriculture applications and an optional additional counterweight is also available for extra machine stability.

A Load Isolation System is another available option to improve stability and reduce material loss when the wheel loader is moving across uneven surfaces.

Durable Components for All-Day Productivity

Built with durable components inside and out, the DEVELON DL250TC-7 wheel loader is designed to maintain uptime and productivity when doing the most challenging unloading and hauling.

It features heavy-duty ZF axles for lifting large bucket loads, a reinforced box frame that provides greater rigidity for improved structural life, and large self-centering, double-tapered roller bearings that better distribute loads.

Wider radiator fin spacing and a standard reversible fan clear dirt, dust, and other large debris to reduce clogging. Brakes are located on the outboard hub, extending the lifetime of the brake discs — and offering convenient maintenance access.

Redesigned Wheel Loader Cab

The wheel loader cab interior offers a roomy, quiet and comfortable environment for operators.

You’ll find frequently used controls within easy reach. There’s 14% more total glass area than on the previous model, including a full glass door that improves visibility. The view from the standard rearview camera appears on the DEVELON Smart Touch display — along with other machine information.

A DEVELON-exclusive Standard Transparent Bucket option gives you a supplemental view “through the bucket” from an in-cab display.

Additional upgrades include an automatic heating and cooling system, air suspension seat and optional electronic steering.

Easy Access to Key Maintenance Areas

Keeping your DL250TC-7 running at peak performance is easier thanks to convenient component access, centralized lubrication points, and accessible fluid-level checks. Vented dust seals and covers help prevent grease overfill. A rear full fender option includes a new lock-and-release handle to maximize fender retention in the closed position — and makes maintenance easier.

DEVELON Fleet Management is standard, giving you the ability to monitor and manage machine maintenance using a user-friendly mobile app. You can also keep track of fleet status, machine location, operating hours, fuel usage, error codes, engine, and hydraulic oil temperatures, and various other data points.

High-Efficiency and Highly Productive

The DEVELON DL250TC-7 features a variety of fuel-saving features, including automatic transmission modes that shift gears to maximize efficiency and standard auto-idle and auto-shutdown features.

Situation Awareness Technology helps save fuel by automatically adjusting engine output in real-time based on the needs of the drivetrain and hydraulics.

To comply with Tier 4 emissions standards, the DL250TC-7 incorporates a high-pressure common-rail fuel delivery system as well as cooled exhaust gas recirculation, combined with a diesel oxidation catalyst and selective catalyst reduction with diesel exhaust fluid.